steel roof structure/prefab steel structures/steel structure shed design

1. Wall and roof materials : EPS/Rockwool/PU/PIR Sandwich Panel

2. Color: normally, white gray, blue and red;

3. Moudle: Single slope or double slop;

4. Window material: Plastic steel or aluminum, swing or slidding

5. Door: EPS Sandwich panel, PU sandwich Panel, Plastic steel or Aluminum.

Material Standards:

1. International standard: Fe360B

2. Chinese standard: Q235B/ Q345B

3. European standard: A37-2

4. Japanese standard: SAPH38(G3133-87)

5. American standard: A283GRC

Function:

Beam, column used as various steel structure beam and column on workshop, warehouse, office building and power plant

Coating:

1. Painting:Alcohol acid paint, epoxy zinc rich paint and chlorinated rubber paint. Various colors

available.

2. Hot dip galvanizing: The hot dip galvanizing thickness is about 60~120 microns and

275~500g/square meters

Detailed Product Description

Prefabricated house

Portable building exported to Australia for miners

Size: 7.8M*3.2M*2.6M

Building area: 24.96m2 with1.8m balcony

Door and window: aluminum alloy Hollow glass, power coated.

With ceiling outside and inside of the room

More than 200sets have been sent to Australia

Features:

1. Reliable structure: light steel structure is the frame of our building, which meets the design requirements of steel structure.

2. Easy to install and disassemble: Standardized components make it easy to install and dismantle. It is especially suitable for emergency projects.

3. Attractive appearance: Because prepainted steel sheet or sandwich panel is adopted, the whole structure is handsome.

4. Environment friendly and economical: Reasonalbe design makes it reusable. The reusable character makes it environment friendly and economical.

5. Cost efficient: First class material, reasonable price, once and for all investment, low requirements for base and short completion time make it cost efficient.

6. Relocatable: It can be relocated up to 10 times. It has 15 to 20 years durability

FAQ

1 . How much time and personnel are required to complete the project with the building system of DreamHouse ?

1.1 . Villa: The construction period varies depending on the size and design. For a villa of 150m ² : 10 days are required for the basic structure and 20 days for decorating with 5 technicians .

1.2 . Mid-size building (home , hotel, office , schools , clinics, etc. ..)

For a 4-storey building with an area of 1500m ² , 20 days are required to complete the basic construction and 10 days for decoration. The number of technicians required is 20.

1.3 . Steel structure warehouse (factory, workshop , showroom , etc. ..)

Construction times vary depending on the size , the plan and the professional skills of workers. A warehouse of 1000m ², 1 month is required for installation and 20 people for the implementation .

1.4 . Other buildings (bungalows, container house , temporary dormitory , etc. ..)

Construction time : 2 days

Number of Technicians: 6

2 . How long does it take to produce a constructive system?

Generally, 30 days are required to produce a villa or a steel structure building steel structure warehouse or after confirming the architectural level. This is indicated in the quote

3 . How many containers required for my project ?

After confirmation of your request , we send our shipping calculate weight and overall dimensions of all building materials department . After the calculation, we send you our answer.

In general, a 40-foot container is required for the transport of a building with an area of 80m2.

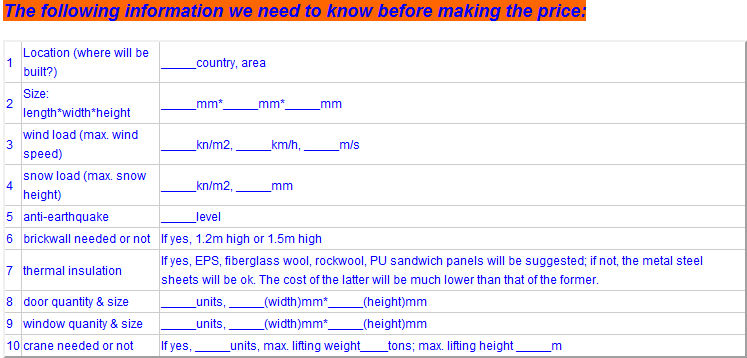

4 . What are the mandatory information to send you to get a quote?

After receiving your first quote, we will send you a complete array that contains all the information we need.

5 . How to ensure that the structure meets the criteria for local buildings ?

Our structures are in line with national and European standards ( Eurocodes 8 TSR ) . We use the latest building technologies and calculations are made according to the rules of art. Finally, an auditor certifies each office building after an on-site inspection .

6 . How to become agent of your company?

First of all, thank you for your interest in our company. Generally , we take as agents that customers who bought our products at a given quantity .

After receiving your request, we will take it into consideration and make a careful assessment .

7.Your buildings are they resistant to hurricanes and earthquakes?

Ideally , the process of construcion based modular steel frames has been developed in Japan to address critical environmental conditions . The strength of steel and modular construction allow the absorption of large loads generated during disasters.

Buildings withstand earthquakes of level 7 on the Richter scale and cyclone with sustained winds up to 100km / h.

8. Do the houses have warranty?

If the goods are damaged in transit , or the house without problems in the case of external damage , we will send you the new goods in the next order. In this case, you can save the high sea freight !

You can call me in every time, 24 hours services, I can speak Chinese, English, Spanish.

Give us your idea, we give a dream house to you!